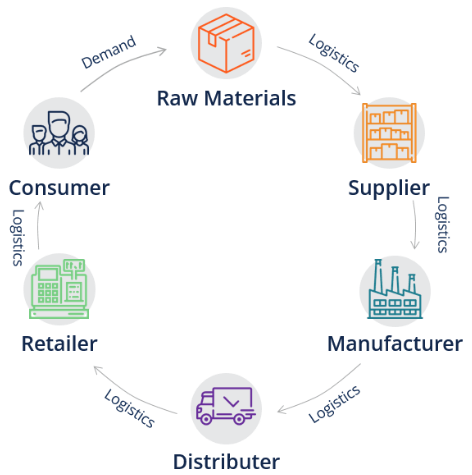

The supply chain is a critical factor in which a company manages the flow of materials and services it supplies in its manufacturing and distribution processes. The supply chain chart can vary according to the company's industry and business model. In general, the supply chain diagram includes various elements such as suppliers, manufacturers, distributors, logistics service providers, retailers and customers. Each link of the supply chain works with other links to ensure that the product or service reaches the customer. Each link of the supply chain works with other links to ensure that the product or service reaches the customer.

A weak spot in the supply chain can negatively impact the company's production capacity and customer satisfaction. Therefore, protecting the supply chain is extremely important for companies in times of crisis.

In times of crisis, various problems may occur in the supply chain. These may include:

1. Supplier Issues: Business partners, including suppliers, may also be affected during times of crisis. A disruption in any link in the supply chain can affect the entire chain. Reasons such as the closure of suppliers, the supply of materials used in production or problems in the provision of logistics services may cause interruptions in the supply chain.

2. Changes in Demand: Significant changes may occur in customer demands during crisis periods. For example, while online shopping increased due to stay-at-home measures during the pandemic period, sales of physical stores decreased. This can cause companies to err in their demand forecasts and have difficulties in stock management in the supply chain.

3. Production Problems: Problems may occur in production during crisis periods. For example, reasons such as natural disasters, technical failures or lack of labor may disrupt or stop production. This can make it difficult for companies to meet customer needs.

4. Logistics Problems: Problems may be experienced in logistics services in times of crisis. For example, travel restrictions, limited logistics facilities or disruptions in customs procedures can cause problems in shipping materials or products.

5. Cost Increase: Costs may increase in times of crisis. For example, logistics costs have increased during the pandemic period due to constraints in the supply chain. This situation can reduce the profit margins of the companies and cause them to experience a financially difficult period.

All these factors require companies to take measures to protect their supply chain and to minimize the effects of crises in times of crisis. First, companies must identify and be prepared for risks in their supply chains. This may include measures such as researching alternative sources of supply, increasing stock levels, forecasting demand, working closely with suppliers, and constantly monitoring supply chain management.

In addition, companies can use digital technologies to reduce risks in their supply chains. For example, technologies such as artificial intelligence and IoT devices can provide greater efficiency and security in supply chain management. Companies should plan how they will manage their suppliers in times of crisis. This may include measures such as communicating closely about issues in the supply chain, monitoring the status of suppliers, being mindful of shipping materials from risky areas, and adopting a solution-oriented approach in collaboration with suppliers.

All of this can help companies protect their supply chains and minimize negative impacts during times of crisis. In addition, companies should prepare a crisis management plan to protect their supply chain. This plan will identify critical elements in supply chain management and provide a roadm p on how to act in times of crisis. A crisis management plan can also provide a framework for minimizing risks in the supply chain, collaborating with suppliers, meeting customer needs and protecting the company's reputation. In addition, in times of crisis, companies should not only focus on their suppliers but also consider other parties in the supply chain to protect their supply chain. This stems from the fact that all parties in the supply chain are interdependent. The weakness of any link in the supply chain can affect the entire supply chain.

The supply chain is one of the key elements of success in today's business world. By managing activities in the supply chain, companies can increase customer satisfaction, reduce costs and increase revenues. However, disruptions in the supply chain can cause serious problems in times of crisis and threaten the business continuity of companies. Especially in a global crisis such as a pandemic, difficulties in the supply chain can affect companies' production capacities, supply processes and logistics operations. Therefore, companies to anticipate risks and crises in the supply chain and develop strategies to effectively combat these crises. These strategies may include close communication with business partners in the supply chain, identifying alternative suppliers, optimizing stock levels, use of productivity-enhancing technologies, and preparation of crisis management plans. All of this can help companies maintain efficiency in their supply chain and ensure business continuity in times of crisis. Times of crisis can present an opportunity for companies to reassess and update their supply chain strategies. During these periods, companies may seek new business models, technologies and processes to increase reliability in the supply chain, provide flexibility and be prepared for possible future crises. This means that the supply chain must be continually improved, not only in times of crisis, but also to adapt to changing conditions in the future. As a result, protecting the supply chain and managing it in times of crisis is vital for companies to ensure business continuity and maintain competitive advantage.

Share:

Related Articles

Understood Employees Contribute and ...

In the corporate world, we often hear statements like: “They’re talented, b ...

The Silent Power of Corporate Succes ...

In today's business world, organizations operate in an environment shaped b ...

Customer Relations and Training in B ...

Bancassurance, a business model in which banks market insurance products to ...

What Awaits the Business World? A St ...

Digitalization is no longer just a technological trend but a necessity for ...

Digital Transformation in Conflict M ...

Conflict is a reality we encounter in all aspects of life. Whether at home, ...

The Road to Success: Market Dynamics ...

In today’s rapidly changing market conditions, the importance of management ...

Leadership in the Digital Age: A New ...

Leadership in the digital age requires embracing continuous learning, innov ...

Mastering Risk Management

Mastering risk management is not merely an option for businesses but a nece ...

International Banking in Germany: A ...

Germany, with its strong industrial structure, high-technology products, an ...

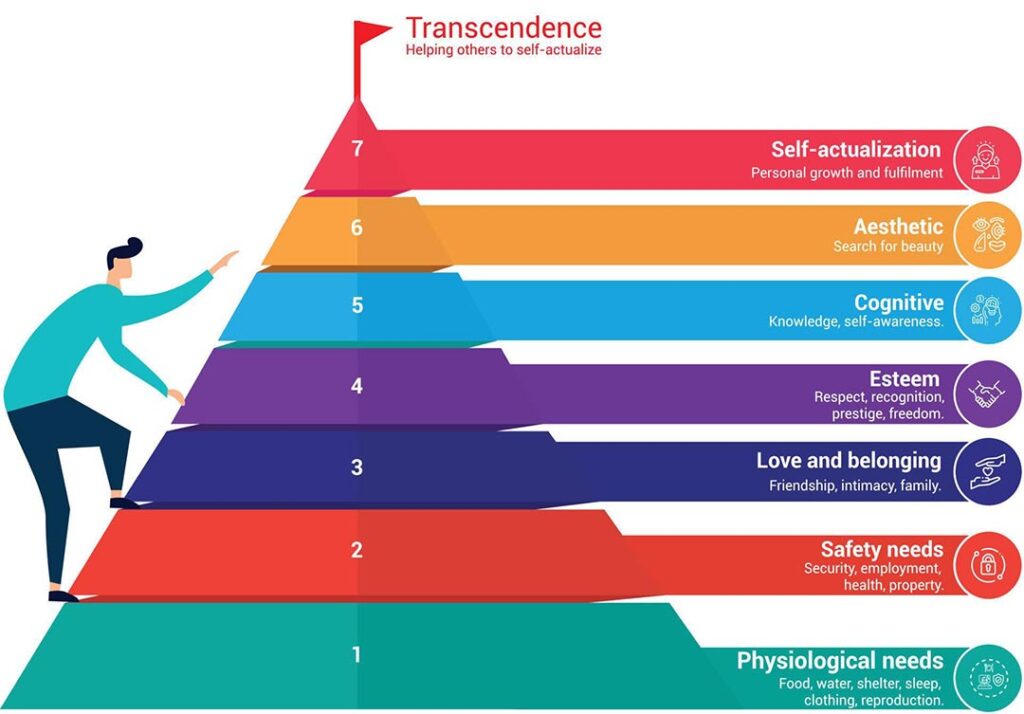

Leadership and Maslow's Hierarchy of ...

Abraham Maslow's hierarchy of needs is a fundamental psychological theory u ...

Leadership and Sustainability of Org ...

Today's business world is characterized by continuous change, technological ...

The Importance of Coaching Skills f ...

The Importance of Coaching Skills for LeadersCoaching skills are essenti ...

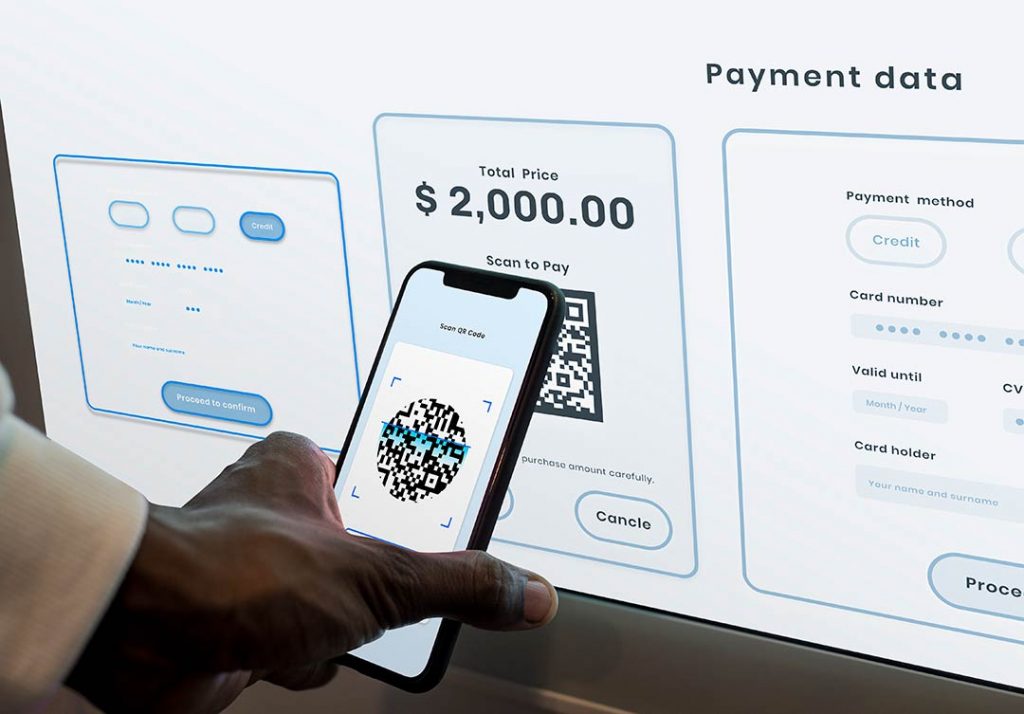

Fintech in Turkey: The Rise of Finan ...

Fintech in Turkey: The Rise of Financial Technology

Bancassurance

Bancassurance is a business model that is among the financial services offe ...

Banking and Frankfurt

When the banking and finance sector in Europe is analyzed, it is seen that ...

Digital Banking and Germany

Digital banking is a banking service where customers can do their banking o ...

Banking in Germany

Euro used since 2002 in The Eurozone, the currency of 19 EU members. There ...

Strategic Communication

Strategic communication plays a critical role in the success of an organiza ...

Importance of Supply Chain

The supply chain is a critical factor in which a company manages the flow o ...

Key to Success: Going Digital

Digital transformation is a transformation process that aims to increase th ...

Welfare

Poverty and inequality are one of the biggest challenges the current societ ...

ChatGPT

ChatGPT, developed by the OpenAI company known for its work and research in ...

What is Emotional Intelligence and w ...

Emotional intelligence (also known as emotional quotient or EQ) is the abil ...

The Importance of Women's Employment ...

Women's participation in the workforce is closely related to the level of d ...

Digital Banking II – Digital Banking ...

A serious step taken for the spread of “digital banking” in Turkey, providi ...

The Perception of Morality within Ma ...

If everybody in the world jumped out of a window, would you? This question ...

Digital Banking

Digital banking is a banking technology that offers customers the opportuni ...

Banking, Artificial Intelligence and ...

We have heard the concepts of metaverse, artificial intelligence and machin ...

Green Asset Ratio

Sustainable finance has an important place among the investments made for t ...

Servant Leadership

There is an effective form of management that we often hear about today: se ...

Sustainability In The Global Banking ...

Before Covid-19 wreaked havoc on the world’s economies, the global banking ...

Revolution of Digital Banking

With the European Central Bank considering to investigate for a digital cur ...

Taking Action and Making Decisions i ...

Uncertainty is the fact that an event is not within the framework of certai ...

Wind of Change

Change is an important concept that must be managed for employees at all le ...

Organizational Justice

“What is justice? Giving water to trees. What is injustice? To give water t ...

Open Banking

Digital transformation has started to show its effects in every aspect of o ...

Digital Literacy And Corporate Life

There are many innovations that managers and employees need to follow in or ...

Financial Literacy

The words money and economy are two important concepts that have a great pl ...

Sustainability and Bank

The solutions we have found to our various needs throughout history and ada ...

Adaptability, Flexibility and Leader ...

Being able to adapt to changing conditions is very, very important not only ...

Creativity and Leadership Relationsh ...

The world is getting more competitive every day. For this reason, the servi ...

Competitive Analysis and Banking Sec ...

Competition analysis requires you to examine your direct and indirect compe ...

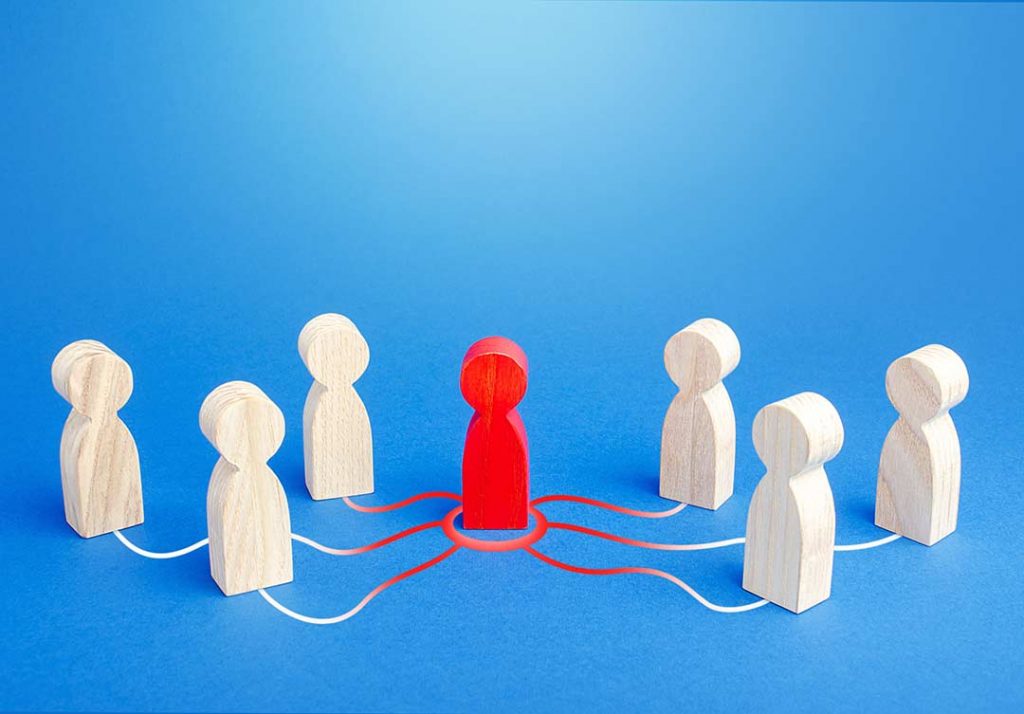

Delegation in Management

The statements "two heads are better than one" or "teamwork makes the dream ...

Climate Change

All creatures evolve to best adapt to environmental impacts. Those who are ...

Change of Banking Service Channels i ...

Global crises such as the pandemic, force the existing structures to change ...

Innovation

It is undeniable that innovation has a very important place in today's worl ...

Artificial Intelligence

Artificial intelligence is no longer just something specific to science fic ...

Entrepreneurship

Entrepreneurship is the process of starting a new business that incorporate ...

Global Leadership

The world is changing day by day and the information we have today is out o ...

Resilience and Leadership

We encounter many events in life that cause us difficulties and stress. How ...

Entrepreneurial Spirit for Leaders

Why is important for success? The conventional perception of entrepreneursh ...

Finance Leadership in a Pandemic

Crises bring along a period in which institutions need to review their fina ...

Crisis Management

Crisis is a state of tension that puts the existence and goals of an organi ...

Strategic Leadership and Pandemic

Strategic Leader is the person who sets the roadmap to achieve the ultimate ...

Awareness, Appreciation, Success

It is very important for a person to recognize himself, discover his power ...

Woman and Career

People who are raised by unemployed mothers have a mother model in their mi ...

Conflict Management

In the broadest sense, conflict is disagreement between two or more people ...

Leading with Kindness

Kindness is an important virtue. Kindness in all areas of life makes relati ...

Smart Meetings

Meeting management is the process of managing all stages and components of ...

Negotiation Management

Negotiation is defined as a dialogue aimed at reaching a common and benefic ...

Virtual Leadership

The repercussions of the digitalization process in business life were sprea ...

Manager and Patience

Patience is an important concept in management. Patience is active, not pas ...

Being All Ears

Human beings differ from other creatures in their way of communicating. Com ...

Networking

The fact that managers in the corporate world act with awareness of network ...

Asking Strong Questions

For managers, asking a strong question is an important skill. Managers, who ...

Managing Yourself

The manager at work is in communication with the other parts of the busines ...

Mental Immunity

In the fight against Coronavirus (Covid-19) pandemic, knowledge and awarene ...